HRE-1250

Hydraulic Elbow Forming Machine

Duct elbow making machine for the production of round duct elbows

HRE-1250

Hydraulic Elbow Forming Machine

Duct elbow making machine for the production of round duct elbows

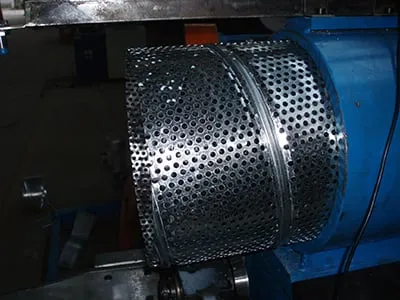

The HRE-1250 hydraulic round elbow forming machine is used for forming the joint bone seam (lock-seam) and pressing it tight on round duct elbows. It is used specifically for manufacturing round elbows by seaming the duct pipe sections together.

The hydraulic round duct elbow making machine can manufacture elbows with a thickness of 0.5-1.2mm. It uses an integrated design for a compact structure. It can produce 90-degree duct elbows in 5 sections. By changing the forming rollers, it can also perform beading (ribbing) and sealing groove formation on the duct pipe sections, achieving the effect of multi-functional operation.

Female joint

Female joint Plasma cutting

Plasma cutting

The table height is adjustable, facilitating the switch between female joint and male joint forming.

By selecting optional beading rollers and grooving rollers, reinforcing ribs and sealing ring grooves can be rolled onto the duct pipe body, enhancing structural rigidity and improving sealing performance.

The hydraulic round elbow forming machine has two working tables, one for flanging (folding the edge) and one for seaming (joining the parts).

The rotation of forming roller is driven by a hydraulic motor with adjustable speed. Roller infeed and retraction are also driven by hydraulic cylinders, resulting in smooth and efficient forming.

- The forming rollers use Cr12 material, vacuum-furnace hardened to a hardness of up to 60°, ensuring a long service life.

- The hydraulic round elbow forming machine uses a 4kW main motor for robust power, driven by a full hydraulic system.

- The duct elbow making machine is additionally equipped with a pressing attachment for pressing shapes onto the duct pipe sections, which facilitates installation and ensures better sealing after the sealing ring is applied.

- The work surface is made of stainless steel, offering superior wear resistance and high flatness.

- The inner material of the pressing area is wear-resistant steel, which is hardened and electroplated for durability.

With over 20 years of experience in the production of duct fabrication machinery, DDJX is a trusted manufacturer serving 1,000+ clients across the HVAC and ventilation industries. Send us your request today.