DRW-700

CNC 2-Roll Duct Rounding Machine

Two-roll round bending machine for shaping metal sheets into cylindrical or conical shapes

DRW-700

CNC 2-Roll Duct Rounding Machine

Two-roll round bending machine for shaping metal sheets into cylindrical or conical shapes

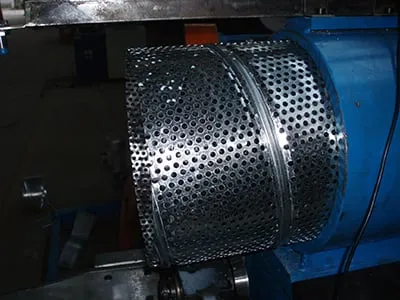

The CNC 2-roll rounding machine uses the precise cooperation between a rubber lower roller and the upper roller. By utilizing the principle of extrusion deformation, it smoothly bends the metal sheet into a preset arc, rolling it into a cylinder with excellent roundness. The finished duct diameter depends on several factors, including material thickness, upper roller diameter, and lower roller height. This duct rounding machine is equipped with multiple dies, allowing for a change in tooling to adapt to different rounding ranges, meeting diverse customer needs.

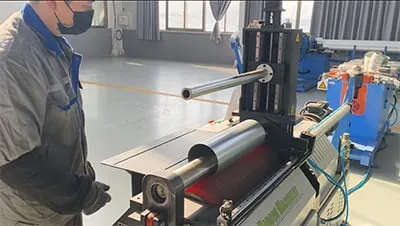

This CNC 2-roll rounding machine is widely used in the manufacturing of various pipe sections, efficiently replacing traditional manual rounding. It is a reliable choice for achieving automation and precise processing.

- Rounding diameter100-600mm

- Metal sheet width700mm

- Metal sheet thickness0.5-1.5mm

- Main motor power5.5kW

- Servo motor power2.2kW

- Voltage380V/50Hz/3Ph

- Machine dimensions2500×900×1600mm

- Machine weight1080kg

The unique rubber lower roller design is particularly adept at handling thin metal sheets, significantly guaranteeing the roundness and quality of the finished product.

The lifting and lowering of lower roller are precisely controlled by a servo system, ensuring accurate positioning.

The CNC 2-roll rounding machine can process thin metal sheets with a thickness range of 0.5-1.5mm and is equipped with a 5.5kW main motor, balancing power with energy efficiency.

The automatic pushing function not only enhances efficiency but also ensures operational safety.

With over 20 years of experience in the production of duct fabrication machinery, DDJX is a trusted manufacturer serving 1,000+ clients across the HVAC and ventilation industries. Send us your request today.