See Other Categories

Which spiral duct machine models balance speed and precision for high-volume daily workshop production?

Which spiral duct machine models balance speed and precision for high-volume daily workshop production?

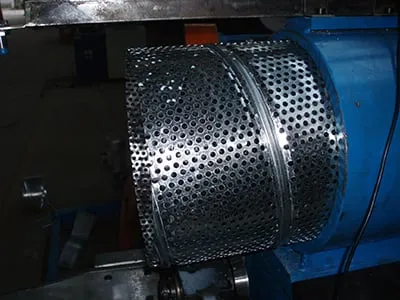

The DDGJ-1.2-1800-ZY (Integrated) and DDGJ-1.2-1800-ZF (Split) models are suitable. Both feature an adjustable feed speed of 35 meters/minute to ensure high production efficiency. They utilize a fixed steel die forming process, which results in a tighter lock-seam and more precise output diameter compared to traditional spread-wing type duct machines, effectively balancing the required speed and precision for mass production.

What is the potential square meter production capacity of the spiral duct machine per day?

What is the potential square meter production capacity of the spiral duct machine per day?

Based on an 8-hour workday and accounting for material change time, the daily production capacity of spiral duct is 1000-1400 square meters.

What is the material loss rate associated with the spiral duct production process?

What is the material loss rate associated with the spiral duct production process?

Due to the formation of the seam as a four-layer folded lock-seam, the resulting material loss rate is approximately 12.5%.

Are there any wear parts or consumables required during spiral duct machine production?

Are there any wear parts or consumables required during spiral duct machine production?

Blades may become dull after multiple cuts but can be sharpened for continued use. Cutting stainless steel accelerates blade wear, so plasma cutting is recommended for that material. Emulsion fluid is the primary consumable.

What are the sites or space requirements for the spiral duct machine?

What are the sites or space requirements for the spiral duct machine?

The spiral duct machine has minimal site requirements. It can be operated at the construction site or mounted on a vehicle for mobile production.