DDGJ-1.2-1800-ZY

Spiral Duct Forming Machine

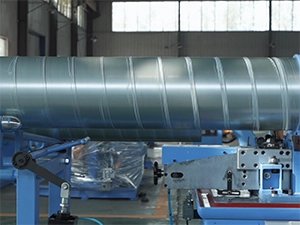

Spiral tubeformer for manufacturing straight round spiral air ducts or helical tubes

DDGJ-1.2-1800-ZY

Spiral Duct Forming Machine

Spiral tubeformer for manufacturing straight round spiral air ducts or helical tubes

- Structure: integrated type, suitable for transportation to the job site

- Spiral duct diameter range: 100mm to 1800mm

- Spiral duct thickness range: 0.5-1.2mm

- Feeding speed: 35 meters/minute, adjustable

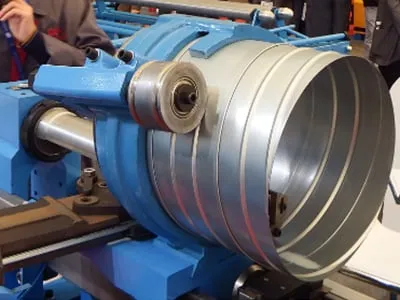

Integrated type spiral duct forming machine is primarily designed for manufacturing spiral duct pipes used in commercial and industrial HVAC ductwork. It efficiently produces galvanized steel ducts (thickness 0.5-1.2mm) and stainless steel ducts (thickness 0.45-1.0mm) within a diameter range of 100mm to 1800mm. The applicable strip width for both materials is consistently 137mm. This spiral duct forming machine utilizes a direct-connect integrated structure, making the entire unit compact for easier transportation to the construction site for on-site duct production. It offers both convenient operation and efficient duct output.

The main motor of the spiral duct machine provides 15kW of output, allowing for a maximum, adjustable feeding speed of up to 35 meters/minute, which supports high production efficiency. The spiral tube forming machine employs a die-forming process; compared to traditional spread-wing type duct machines, this method results in a tighter lock-seam and a more precise output diameter, ensuring consistency and reliability in duct formation.

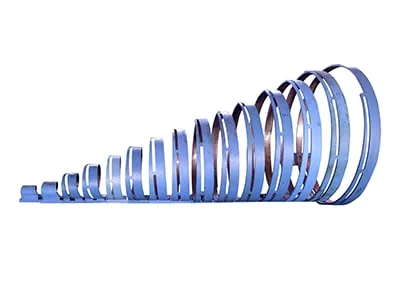

Spiral duct pipes

Spiral duct pipes

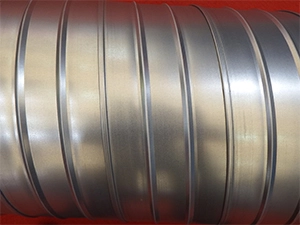

Beaded spiral duct pipe

Beaded spiral duct pipe

- Spiral duct diameter range100-1800mm

- Thickness range (Galvanized steel)0.5-1.2mm (strip width 137mm)

- Thickness range (Stainless steel)0.45-1.0mm (strip width 137mm)

- Uncoiler (Coil inner diameter)460-520mm

- Uncoiler (Max. coil outer diameter)1100mm

- Uncoiler (Max. coil weight)1200kg

- Lock-seam typeExternal lock-seam

- Feeding speed0-35 meters/minute (adjustable)

- Cutting methodRolling shear cutting or plasma cutting

- Power systemCutting and flipping use pneumatic power; feeding roller clamping uses hydraulic power

- Forming die materialSteel

- Machine weight2000kg

- Machine dimensions3.4×1.7×1.7m

- Discharge rack size2.1×1.0×1.0m

- Total power16kW

- Power supply380V/50Hz/3Ph

- Control methodTouch screen

This steel strip uncoiling unit features a vertical, integrated structure connected to the main spiral duct forming unit. It is equipped with a pneumatic brake for controlled wear. A steel strip buffering device is equipped to prevent coil loosening and facilitate feeding. It supports coils with an inner diameter of 460-520mm, a maximum outer diameter of 1200mm, and a maximum load of 1100kg. Steel coils with excessively large outer diameters are not recommended due to the uncoiler's proximity to the main spiral duct forming unit.

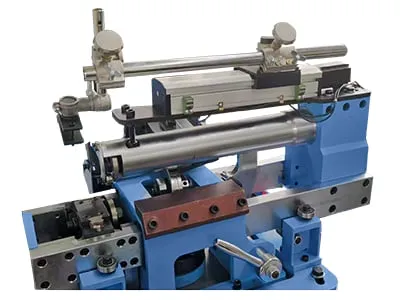

Provides a smooth, clean edge with no contamination, but requires re-adjustment of cutting angle and blade gap when changing dies or material thickness.

Is suitable for any duct pipe diameter and thickness, but produces more smoke and dust during cutting.

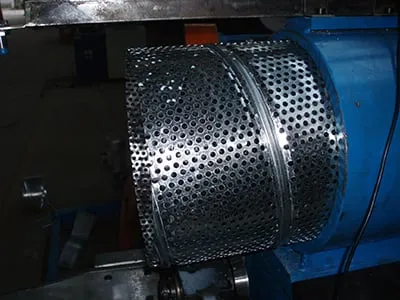

This spiral duct machine is equipped with two sets of rolling mechanisms, suitable for producing spiral duct pipes with thicknesses ranging from 0.5-1.0mm and 1.0-1.2mm, respectively.

The spiral duct forming die is a fixed steel die with an embedded copper layer to enhance service life. The copper layer is replaceable, offering a cost-effective alternative to replacing the entire die. The forming die is wear-resistant, dimensionally accurate, and supports diameters from 100mm to 1800mm.

The height of this duct support rack is adjustable. It features a pneumatic flipping function for supporting ducts under 500mm in diameter. Each rack can accommodate ducts 2-4 meters long, and multiple racks are available as an option.

The wiper board is used to clean the surface of duct.

Available in single-wave and double-wave styles, installed directly on the die. It is generally used to bead ducts with a diameter of 300-1000mm to increase strength.

With over 20 years of experience in the production of duct fabrication machinery, DDJX is a trusted manufacturer serving 1,000+ clients across the HVAC and ventilation industries. Send us your request today.