DPCS-2-2000-ZY

Spiral Duct Forming Machine

Spiral tubeformer for manufacturing straight round spiral air ducts or helical tubes

DPCS-2-2000-ZY

Spiral Duct Forming Machine

Spiral tubeformer for manufacturing straight round spiral air ducts or helical tubes

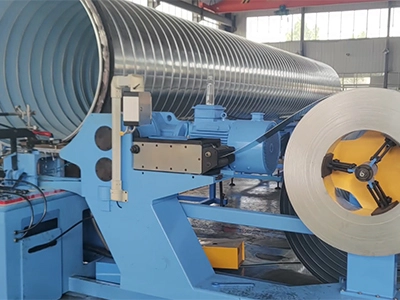

- Structure: integrated type, suitable for transportation to the job site

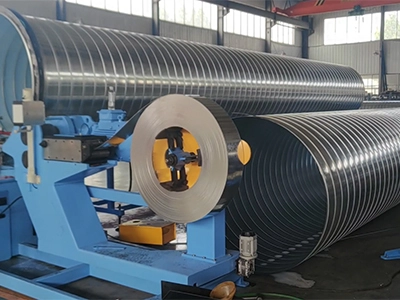

- Spiral duct diameter range: 200mm to 2000mm

- Spiral duct thickness range: 1.2-2mm

- Single duct pipe length: 12 meters

- Feeding speed: 25 meters/minute, adjustable

This spiral duct forming machine is specifically engineered for the production of large-diameter, heavy-gauge spiral ducts. It is capable of manufacturing duct pipes up to 2000mm in diameter, with a maximum thickness of 2.0mm, and a maximum single duct pipe length of 12 meters. Utilizing a direct-connect integrated structure, the spiral duct machine maintains a compact and robust design. This allows for transport to the construction site, supporting highly efficient on-site manufacturing and significantly boosting the flexibility and efficiency of large-scale ventilation projects.

The heavy-gauge, large-diameter spiral ducts produced by this spiral duct pipe forming equipment are widely used in the following scenarios requiring medium-to-high pressure and high mechanical strength:

- Protection casing for insulated water supply pipes.

- Ventilation and dust collection systems in heavy industrial plants.

- Air conveyance in large facilities such as subway tunnels and underground spaces.

- Marine ventilation and air conditioning supply systems for large sports venues.

- High-temperature exhaust systems and other ventilation environments requiring high pressure resistance and durability.

- Spiral duct diameter range200-2000mm

- Thickness range Galvanized steel1.2-2.0mm (strip width 200mm)

- Thickness range Stainless steel1.0-1.5mm (strip width 200mm)

- Uncoiler Coil inner diameter460-520mm

- Uncoiler Max. coil outer diameter1400mm

- Uncoiler Max. coil weight1500kg

- Lock-seam typeExternal lock-seam

- Feeding speed0-25 meters/minute (adjustable)

- Cutting methodPlasma cutting

- Power systemCutting and flipping use pneumatic power; feeding roller clamping uses hydraulic power

- Forming die materialSteel

- Machine weight3000kg

- Machine dimensions4.0×2.15×1.7m

- Discharge rack size2.1×1.0×1.2m

- Total power23kW

- Power supply380V/50Hz/3Ph

- Control methodTouch screen

Powerful drive system: Equipped with a 23kW main motor, the system provides ample power to stably process metal coil materials ranging from 1.2-2.0mm in thickness. The feeding speed reaches 25 meters/minute, which ensures high production efficiency while safeguarding forming quality.

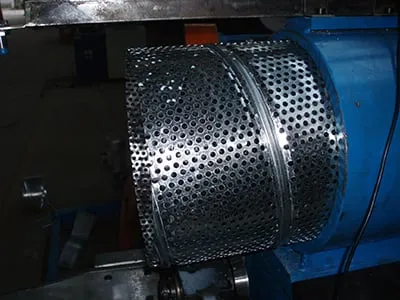

High-precision die forming: The spiral duct forming machine employs a die-forming process, which creates a secure lock-seam with superior airtightness. This method ensures accurate diameter control and excellent consistency, outperforming traditional spread-wing type duct machines.

Wide steel strip design: Supporting 200mm wide material, this feature substantially improves sheet utilization efficiency and minimizes necessary seams or material waste, which is particularly beneficial for manufacturing long, large-diameter ductwork.

Compact and portable structure: The direct-connect integrated design balances rigidity with portability, enabling quick deployment to different sites for on-site spiral duct fabrication.

With over 20 years of experience in the production of duct fabrication machinery, DDJX is a trusted manufacturer serving 1,000+ clients across the HVAC and ventilation industries. Send us your request today.